How is the reliability of semiconductor equipment precision parts guaranteed in extreme environments?

Release Time : 2025-06-03

In the context of the rapid development of modern science and technology, semiconductor equipment is widely used in extreme environments such as aerospace, military equipment, and deep-sea exploration. These environments are often accompanied by factors such as high temperature, low temperature, strong vibration, radiation, and high humidity, which put forward extremely high reliability requirements for semiconductor equipment precision parts in semiconductor equipment. In order to ensure that these key components can still operate stably under extreme conditions, comprehensive consideration and systematic improvement must be made from multiple aspects such as material selection, design optimization, manufacturing process, packaging technology, and test verification.

Material selection and performance optimization

Materials are the basis for determining the reliability of semiconductor equipment precision parts. In extreme environments, ordinary metals or plastics may not be able to withstand drastic temperature changes or chemical corrosion. Therefore, engineers usually choose special materials with excellent thermal stability, corrosion resistance, and mechanical strength, such as titanium alloys, ceramic-based composites, and high-temperature resistant polymers. In addition, for certain specific applications (such as space environments), the radiation resistance of the material must also be considered. For example, anti-radiation coatings or doping with specific elements are used to improve the stability of the material, thereby extending the service life of the parts and reducing the failure rate.

Structural design and thermal management

In extreme environments, thermal stress is often one of the main reasons for the failure of precision parts. Therefore, in the structural design stage, it is necessary to predict the deformation of parts at different temperatures through simulation analysis, and optimize their geometry accordingly to reduce the stress concentration problem caused by uneven thermal expansion. At the same time, a good thermal management system is also an indispensable part, including the use of high-efficiency thermal conductive materials, heat sinks, phase change cooling technology and other means to ensure that the equipment can still maintain a stable operating temperature in a high temperature environment to avoid overheating damage.

High-precision manufacturing and surface treatment

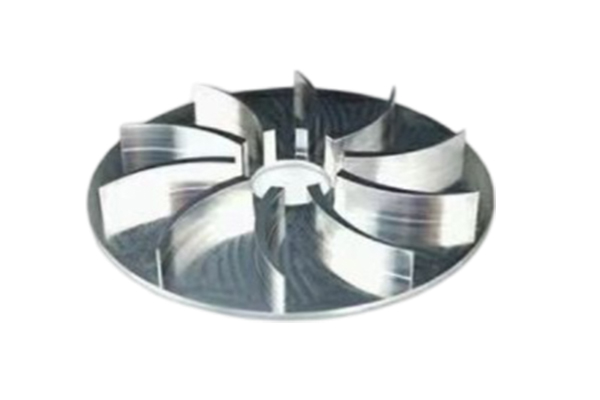

The manufacturing accuracy of precision parts directly affects their performance under extreme conditions. Many key components in modern semiconductor equipment, such as valves, sensors and micromotors, require nanometer-level processing accuracy. To this end, companies generally use ultra-precision processing technologies, such as electron beam lithography and ion beam etching, to ensure high consistency of part dimensions. In addition, surface treatment technology is also crucial, such as electroplating, chemical plating, anodizing, etc. to enhance the wear resistance, corrosion resistance and conductivity of parts, thereby further improving their reliability in harsh environments.

Packaging and protection technology

Even if the parts themselves have good physical and chemical properties, effective packaging and protection measures are still needed in extreme environments to resist external influences. Common packaging methods include airtight packaging, vacuum packaging and moisture-proof packaging, which can effectively prevent the intrusion of moisture, oxygen and harmful gases. In addition, for active parts exposed to the outside, sealing rings, grease coatings and other means can also be used for protection to reduce the risks of wear and contamination. In aerospace applications, multi-layer shielding structures are even used to resist the interference of cosmic rays to ensure the long-term stable operation of the system.

Testing, verification and quality control

Before the product is put into use, it must undergo a rigorous testing and verification process to ensure its reliability in extreme environments. This includes high and low temperature cycle tests, vibration and shock tests, accelerated aging tests, EMC (electromagnetic compatibility) tests, etc. By simulating the real working environment, the performance changes of parts under various extreme conditions are detected, and potential defects are discovered and improved in a timely manner. At the same time, a complete quality management system is established. From raw material procurement to final assembly and delivery, each link must strictly implement standardized operating procedures to ensure that each product can meet demanding application requirements.

Ensuring the reliability of semiconductor equipment precision parts in extreme environments is a systematic project that requires coordinated efforts in all aspects from materials, design, manufacturing, packaging to testing.

Material selection and performance optimization

Materials are the basis for determining the reliability of semiconductor equipment precision parts. In extreme environments, ordinary metals or plastics may not be able to withstand drastic temperature changes or chemical corrosion. Therefore, engineers usually choose special materials with excellent thermal stability, corrosion resistance, and mechanical strength, such as titanium alloys, ceramic-based composites, and high-temperature resistant polymers. In addition, for certain specific applications (such as space environments), the radiation resistance of the material must also be considered. For example, anti-radiation coatings or doping with specific elements are used to improve the stability of the material, thereby extending the service life of the parts and reducing the failure rate.

Structural design and thermal management

In extreme environments, thermal stress is often one of the main reasons for the failure of precision parts. Therefore, in the structural design stage, it is necessary to predict the deformation of parts at different temperatures through simulation analysis, and optimize their geometry accordingly to reduce the stress concentration problem caused by uneven thermal expansion. At the same time, a good thermal management system is also an indispensable part, including the use of high-efficiency thermal conductive materials, heat sinks, phase change cooling technology and other means to ensure that the equipment can still maintain a stable operating temperature in a high temperature environment to avoid overheating damage.

High-precision manufacturing and surface treatment

The manufacturing accuracy of precision parts directly affects their performance under extreme conditions. Many key components in modern semiconductor equipment, such as valves, sensors and micromotors, require nanometer-level processing accuracy. To this end, companies generally use ultra-precision processing technologies, such as electron beam lithography and ion beam etching, to ensure high consistency of part dimensions. In addition, surface treatment technology is also crucial, such as electroplating, chemical plating, anodizing, etc. to enhance the wear resistance, corrosion resistance and conductivity of parts, thereby further improving their reliability in harsh environments.

Packaging and protection technology

Even if the parts themselves have good physical and chemical properties, effective packaging and protection measures are still needed in extreme environments to resist external influences. Common packaging methods include airtight packaging, vacuum packaging and moisture-proof packaging, which can effectively prevent the intrusion of moisture, oxygen and harmful gases. In addition, for active parts exposed to the outside, sealing rings, grease coatings and other means can also be used for protection to reduce the risks of wear and contamination. In aerospace applications, multi-layer shielding structures are even used to resist the interference of cosmic rays to ensure the long-term stable operation of the system.

Testing, verification and quality control

Before the product is put into use, it must undergo a rigorous testing and verification process to ensure its reliability in extreme environments. This includes high and low temperature cycle tests, vibration and shock tests, accelerated aging tests, EMC (electromagnetic compatibility) tests, etc. By simulating the real working environment, the performance changes of parts under various extreme conditions are detected, and potential defects are discovered and improved in a timely manner. At the same time, a complete quality management system is established. From raw material procurement to final assembly and delivery, each link must strictly implement standardized operating procedures to ensure that each product can meet demanding application requirements.

Ensuring the reliability of semiconductor equipment precision parts in extreme environments is a systematic project that requires coordinated efforts in all aspects from materials, design, manufacturing, packaging to testing.