Semiconductor equipment precision partsHow can the advantages of micro-machining technology meet the needs of equipment miniaturization?

Release Time : 2025-06-26

Semiconductor equipment precision parts Micro-machining technology can break through the limitations of traditional processing methods and produce parts with smaller size and finer structure. In semiconductor equipment, many key components need to realize specific functions at the microscopic scale, such as some tiny sensors, valves and channels. Micro-machining technology can process micron or even nano-level structures on the surface or inside of parts by adopting advanced laser processing, electron beam processing, ion beam processing and other technologies. This is like carving a complex pattern on a very thin piece of paper. Traditional tools are difficult to achieve such fine operations, but micro-machining technology can easily do it. These fine structures can meet the requirements of higher functional integration of parts after the miniaturization of semiconductor equipment, so that the equipment can still have powerful performance while reducing its size.

Micro-machining technology allows multiple functions to be integrated into a tiny part. With the trend of miniaturization of semiconductor equipment, space has become extremely precious. Through micro-machining, structures with multiple functions can be manufactured in a very small area, such as integrating sensors, actuators and circuits. This is similar to integrating the functions of a complex electronic device into a small chip, which not only saves space but also improves the overall efficiency and reliability of the equipment. For example, in some miniature semiconductor testing equipment, micro-processed parts can simultaneously realize sample collection, detection and analysis functions, greatly reducing the size and number of components of the equipment, and meeting the needs of equipment miniaturization.

Traditional processing methods often produce a lot of material waste when manufacturing small parts. The micro-processing process has a high material utilization rate. It can perform precise processing in specific areas of the material, remove unnecessary parts, and retain the structure required to achieve the function. This is like using a precise scalpel to only remove diseased tissue without damaging the surrounding healthy tissue. In the manufacture of semiconductor equipment precision parts, many materials are expensive. The micro-processing process can maximize the use of materials and reduce production costs. At the same time, it also meets the requirements of equipment miniaturization for efficient use of materials.

The micro-processing process can achieve a high degree of consistency in the size and shape of parts, thereby improving the performance stability of parts. In semiconductor equipment, even small differences in parts may have a significant impact on the performance of the equipment. Micro-processing ensures that the size and shape of each part meet the design requirements by precisely controlling the processing parameters, reducing the fluctuation of equipment performance caused by part differences. For example, in some high-precision semiconductor etching equipment, the nozzle of micro-machining can ensure that the etching liquid is evenly sprayed onto the surface of the wafer to ensure the consistency of the etching effect, which is crucial for the miniaturization and high-performance operation of the equipment.

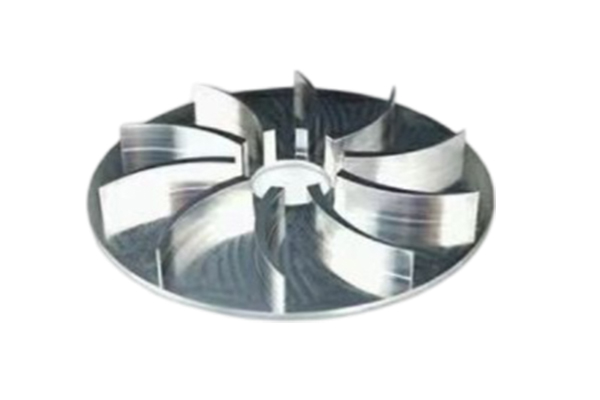

After the miniaturization of semiconductor equipment, the geometric shapes of parts are often more complex. Micro-machining technology has a high degree of flexibility and can produce various complex geometric shapes, such as curved surfaces, micro-holes, micro-grooves, etc. This is like a skilled sculptor who can shape various strange shapes according to design requirements. In semiconductor equipment, these complex geometric shapes can be used to achieve specific functions such as fluid control and optical transmission. For example, in some miniature semiconductor optical devices, micro-machined lenses and reflectors have complex curved surface shapes, which can accurately control the propagation direction of light and meet the requirements of the equipment for optical performance.

The rapid prototyping capability of micro-machining technology can shorten the research and development cycle of semiconductor equipment precision parts. In the research and development process of equipment miniaturization, parts need to be continuously designed and improved. Micro-machining technology can produce samples in a short time for R&D personnel to test and verify. This is like using 3D printing technology to quickly create a building model during the architectural design process, so that designers can intuitively see the design effect, find problems in time and make modifications. Through rapid iteration of design, R&D personnel can find the optimal part design solution faster, accelerate the development of equipment, and meet the market's rapid demand for miniaturized semiconductor equipment.

The advantages of micro-machining technology work together to promote the overall miniaturization of semiconductor equipment. By manufacturing more sophisticated, more integrated, and more stable parts, semiconductor equipment can continue to shrink in size while maintaining or even improving performance. This not only makes semiconductor equipment easier to carry and install, but also provides the possibility for the application of the semiconductor industry in more fields, such as mobile terminals, wearable devices, etc. With the continuous advancement of micro-machining technology, the trend of miniaturization of semiconductor equipment will become more obvious, bringing new opportunities and challenges to the development of the semiconductor industry.