How does the precise structural design of vibration plate connector accessories in the petroleum industry improve connection accuracy?

Release Time : 2025-06-30

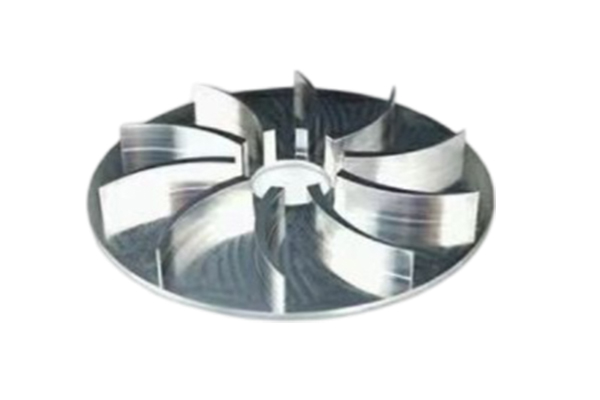

The precision structural design of vibration plate connector accessories in the oil industry focuses on the fine processing of each part from the source. During the manufacturing process, strict requirements are imposed on the shape, size and surface accuracy of each component. Each component is carefully carved, with a smooth and flat surface and minimal error, just like the parts of precision instruments. This fine processing allows the components to fit perfectly, laying a solid foundation for precise connection, avoiding misalignment or loosening of the connection caused by component size deviation, and ensuring that the connector has a high initial accuracy when installed.

In terms of structural layout, the precision-designed connector accessories fully consider the mechanical principles and the working characteristics of the vibration plate. The position, angle and connection method of each component are scientifically planned so that the force can be evenly distributed during the transmission process. When the vibration plate is working, the connector accessories can accurately transmit power and vibration to the specified position without force displacement or loss. Just like building a stable bridge, the reasonable structural layout allows the connector accessories to remain stable in a complex working environment, thereby ensuring the accuracy of the connection and giving full play to the working performance of the vibration plate.

The precision structure of vibration plate connector accessories is also reflected in its unique positioning design. Through special slots, protrusions or grooves, the corresponding positions can be found quickly and accurately during installation to achieve precise docking. These positioning structures are like the interfaces of a puzzle. They can only fit perfectly in the right position, effectively avoiding randomness and errors during the installation process. Once installed in place, this positioning structure can also play a stabilizing role during the operation of the vibration plate, preventing the connector accessories from being displaced due to factors such as vibration, and always maintaining the precise state of the connection.

In order to further improve the connection accuracy, the vibration plate connector accessories with precision structural design also use special locking devices. These locking devices can firmly lock the components after the connector is installed. They do not simply fix the components together, but through clever mechanical design, while ensuring a tight connection, they do not affect the relative motion accuracy between the components. When the vibration plate is running, the locking device can effectively prevent the connector from loosening, ensuring that the connection part is always in a precise state, and maintaining a stable connection effect even under long-term vibration and complex force conditions.

In terms of material selection and application, the precision structural design also fully considers the impact on connection accuracy. The selected materials not only have good strength and toughness, but also have stable physical and chemical properties. In harsh oil industry environments such as high temperature and high pressure, the material will not be significantly deformed or degraded due to environmental changes. This allows the connector accessories to maintain their original structural dimensions and shapes during long-term use, thereby ensuring that the accuracy of the connection is not affected and that they can continue to function stably.

In addition, connector accessories with precision structural design also focus on compatibility with vibration plates and other related equipment. Its structural dimensions, interface forms, etc. are precisely matched with the vibration plate, and can be seamlessly connected with the vibration plate and other equipment during installation and use. This adaptability is not only reflected in physical connection, but also includes precise coordination in signal transmission, power transmission, etc. The collaborative work between various devices further improves the connection accuracy of connector accessories and ensures the stable operation of the entire oil industry equipment system.

The precision structural design of vibration plate connector accessories in the oil industry improves the connection accuracy in all aspects from installation to operation through the combined effect of multiple factors such as fine parts processing, scientific structural layout, unique positioning and locking devices, appropriate material selection, and good equipment adaptability. This precise connection not only ensures the normal operation of the vibration plate, but also provides a strong guarantee for the efficient and stable production of the oil industry.