What is the key role of ultra-high surface smoothness in the manufacturing of semiconductor equipment precision parts?

Release Time : 2025-07-11

In the microscopic world of science and technology, semiconductor equipment precision parts are like a group of "invisible artists". They do not show their true colors, but quietly carve the foundation of modern electronic civilization on the nanoscale stage. Each part carries extremely high technical requirements and craftsmanship. When these parts are made of alumina ceramics, they are not just functional, but more like a "high-tech artwork" that combines science, aesthetics and extreme performance.

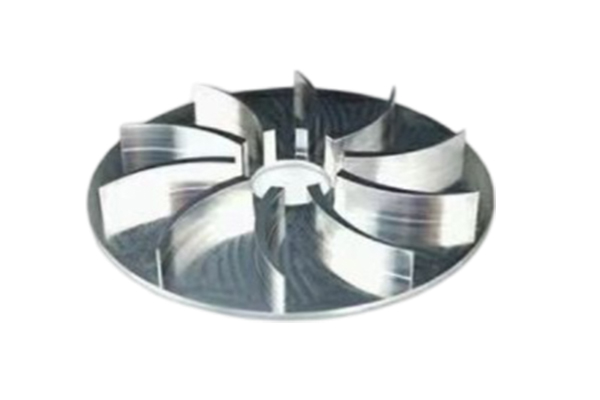

Alumina ceramics are the core material of semiconductor equipment precision parts. It stands out for its excellent corrosion resistance, high insulation, ultra-high surface smoothness and cleanliness. This material can not only remain stable in extreme environments, but also withstand breakdown voltages of up to thousands of volts, making it an indispensable key component in semiconductor manufacturing. From wafer transfer systems to plasma etching chambers to electrostatic chuck components, alumina ceramic parts always play the role of "behind-the-scenes guardians" to ensure the stability and purity of the entire manufacturing process.

Interestingly, these seemingly cold industrial parts actually contain unique beauty. Alumina ceramic semiconductor equipment precision parts themselves present a warm jade-like milky white luster. Under the light, its surface is as smooth as a mirror, and almost no flaws can be seen. This extreme smoothness not only improves the physical properties of the parts, but also allows it to show a low-key elegance in high-end equipment. Some products will also be laser engraved or finely polished to give them a more design-oriented appearance, so that the originally "cold" semiconductor equipment can also reveal a hint of technological temperature.

From a manufacturing perspective, the processing of semiconductor equipment precision parts can be called an "ultimate challenge in the microscopic world." In order to meet the requirements of ultra-high cleanliness, the production process must be carried out in a clean room environment to avoid any particulate contamination; in order to achieve nano-level surface accuracy, ultra-precision CNC equipment and special grinding processes must be used. Every link is like carving a miniature sculpture, which tests both technology and patience.

More importantly, the stability of semiconductor equipment precision parts is directly related to the yield and quality of semiconductor products. In the chip manufacturing process, even a tiny particle of pollution or an unstable electric field may cause the entire batch of wafers to be scrapped. The alumina ceramic parts provide a solid guarantee for this precision battle with its "zero defect" standard. It is not only resistant to acid and alkali, high temperature, but also has excellent wear resistance and chemical inertness, and can serve for a long time in harsh environments without losing performance.

As the semiconductor industry moves towards higher integration and smaller processes, the requirements for equipment parts are becoming increasingly stringent. Alumina ceramic parts semiconductor equipment precision parts are shining in the fields of advanced packaging, EUV lithography, deposition and etching equipment with their unique advantages. It not only supports the backbone of modern chip manufacturing, but also becomes one of the important symbols of a country's high-end manufacturing level.

It can be said that although semiconductor equipment precision parts are hidden inside complex machines, they tell the power of science and technology with their extreme performance. They silently guard every transition of current, carry the most delicate electronic world with their hard bodies, and inadvertently become the most respectable "unsung heroes" in modern manufacturing.

Alumina ceramics are the core material of semiconductor equipment precision parts. It stands out for its excellent corrosion resistance, high insulation, ultra-high surface smoothness and cleanliness. This material can not only remain stable in extreme environments, but also withstand breakdown voltages of up to thousands of volts, making it an indispensable key component in semiconductor manufacturing. From wafer transfer systems to plasma etching chambers to electrostatic chuck components, alumina ceramic parts always play the role of "behind-the-scenes guardians" to ensure the stability and purity of the entire manufacturing process.

Interestingly, these seemingly cold industrial parts actually contain unique beauty. Alumina ceramic semiconductor equipment precision parts themselves present a warm jade-like milky white luster. Under the light, its surface is as smooth as a mirror, and almost no flaws can be seen. This extreme smoothness not only improves the physical properties of the parts, but also allows it to show a low-key elegance in high-end equipment. Some products will also be laser engraved or finely polished to give them a more design-oriented appearance, so that the originally "cold" semiconductor equipment can also reveal a hint of technological temperature.

From a manufacturing perspective, the processing of semiconductor equipment precision parts can be called an "ultimate challenge in the microscopic world." In order to meet the requirements of ultra-high cleanliness, the production process must be carried out in a clean room environment to avoid any particulate contamination; in order to achieve nano-level surface accuracy, ultra-precision CNC equipment and special grinding processes must be used. Every link is like carving a miniature sculpture, which tests both technology and patience.

More importantly, the stability of semiconductor equipment precision parts is directly related to the yield and quality of semiconductor products. In the chip manufacturing process, even a tiny particle of pollution or an unstable electric field may cause the entire batch of wafers to be scrapped. The alumina ceramic parts provide a solid guarantee for this precision battle with its "zero defect" standard. It is not only resistant to acid and alkali, high temperature, but also has excellent wear resistance and chemical inertness, and can serve for a long time in harsh environments without losing performance.

As the semiconductor industry moves towards higher integration and smaller processes, the requirements for equipment parts are becoming increasingly stringent. Alumina ceramic parts semiconductor equipment precision parts are shining in the fields of advanced packaging, EUV lithography, deposition and etching equipment with their unique advantages. It not only supports the backbone of modern chip manufacturing, but also becomes one of the important symbols of a country's high-end manufacturing level.

It can be said that although semiconductor equipment precision parts are hidden inside complex machines, they tell the power of science and technology with their extreme performance. They silently guard every transition of current, carry the most delicate electronic world with their hard bodies, and inadvertently become the most respectable "unsung heroes" in modern manufacturing.